Freecooling projects

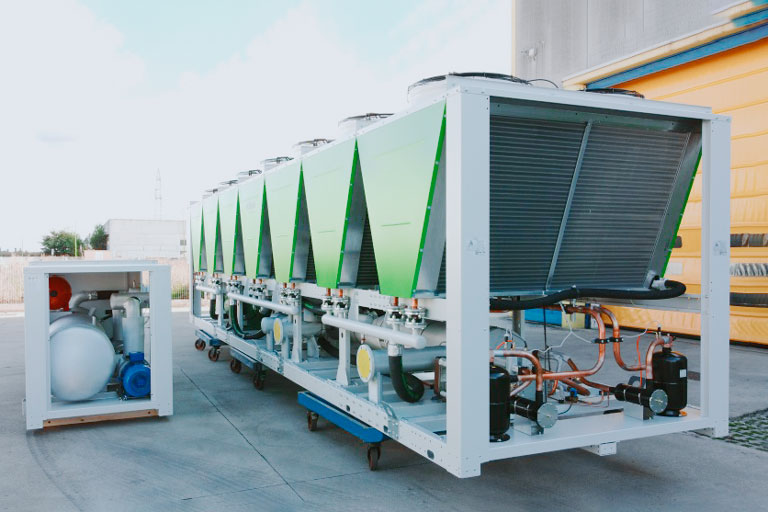

Twin customized chiller, designed for process cooling application (plastic application), each chiller designed with one compressor under inverter per refrigerant circuit, double pump (duty stand-by) both under inverter to follow charge load and flow rate load, tought not only to follow customer thermal loads but also to save energy based on direct optimized freecooling solution.

- Application: Process cooling

-

Installation country:

The main features of this unit are the partial desuperheater, which allows to recover 19 kW from compressors discharge hot gas and the integrated free-cooling coil where the process fluid is cooled by the ambient air, saving a lot of energy with a reduced payback period of the initial investment compared to a normal chiller.

- Application: Machine tools

-

Installation country:

Small process chiller with brazed-plate evaporator and stainless steel water circuit with integrated pump and free-cooling coils which reduce the energy consumption.

- Application: Farmaceutical

- Installation country: Overseas countries

HITEMA freecooling chiller Model ENRF.022 has been designed with coaxial evaporator placed inside a carbon steel tank and the high head pressure pump suitable to work with high glycol concentration.

- Application: Food and beverage

-

Installation country:

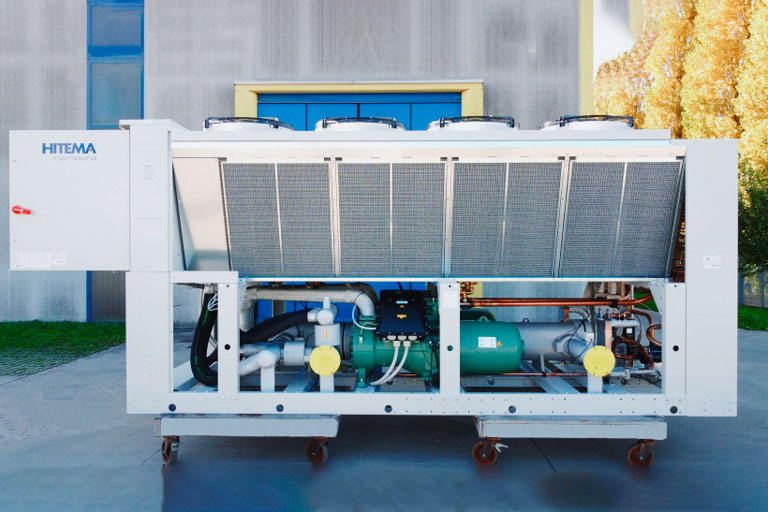

HITEMA Big Chiller model ISVF-680 has been designed to guarantee an high efficiency with high energy and money savings.

- Application: Chemical process

-

Installation country:

Everything in this unit is design for high efficiency: two screw compressors (one per circuit) with three partialization steps each, EC fans to better control the condensing temperature, optimized condenser coils to lower the condensing temperature and free-cooling coils to take advantage of the low temperatures in Russia.

- Application: Plastic processing

-

Installation country:

Efficiency is the key word linked to this unit: two screw compressors with 3 steps of partialization each to better follow the cooling demand, EC fans to better follow the ambient variation, special condenser to reduce condensing temperature and integrated free-cooling coils to save energy using low ambient temperatures to cool down the water, shutting off the compressors.

- Application: Plastic process

-

Installation country: